Case Study: Trusted Electronic Assembly Manufacturing with NPI Solutions

Industry: Marine Research Technology

The Challenge

Recently, NPI Solutions was approached by a revolutionary marine research company with unique challenges and specific needs for electronic assembly manufacturing including the packaging of sensitive data measuring electronics and vision systems. This company is actively conducting advanced research studies in northern oceans and seas where rough waves, salinity, and freezing temperatures pose a significant obstacle to the efficacy of their technology.

The focus of the marine research company was on advancing the efficiency of off-shore fish farming methods using electronic measures to track the behavior of fish, monitor possible disease spread, and track how environmental conditions were impacting the overall health of the fish.

This company sought out the expert engineers and technicians at NPI Solutions for their specific knowledge of electronic assembly manufacturing to provide meaningful design feedback for a product that would withstand challenging underwater conditions and continual exposure to corrosive ocean conditions on surrounding docks. As with the majority of our projects, NPI engineers and technicians looked to empower the client with critical feedback and industry experience that allowed them to reach their goals and final realizations of product designs.

(NPI Solutions maintains non-disclosure agreements with all clients. As a result certain specifics—such as client names, confidential project data, and detailed use case information—are omitted from this case study.)

The Solution

By implementing a joint design and manufacturability process early in the concept phase of the product, the marine research company benefited from NPI’s “Front Line” experience in the design and manufacturing of products that are exposed to many types of conditions.

This specific project had six distinct challenges that needed to be addressed by NPI Solutions to meet the customer requirements. Each separate facet of the project required NPI’s industry knowledge and wealth of experience in electronic assembly manufacturing techniques.

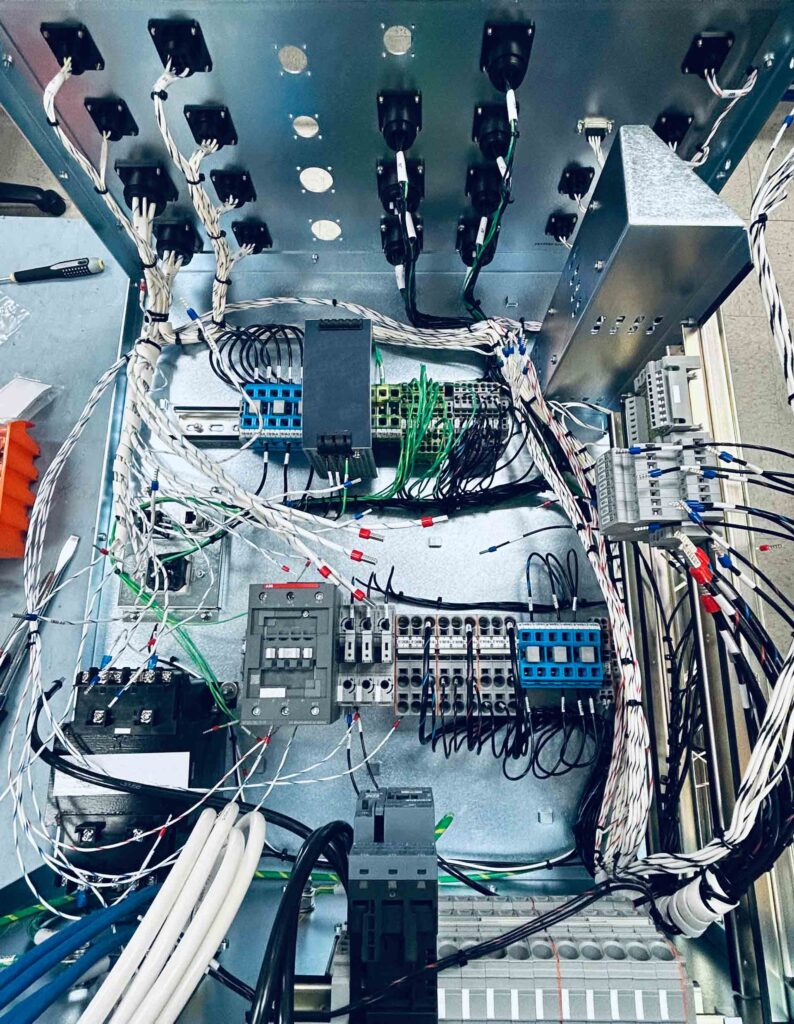

1. Cabinet design

NPI had to design and develop a watertight cabinet that could provide the necessary insulation to the sensitive data measuring electronics and vision systems used to monitor fish health.

2. Component placement in the cabinet

A secondary consideration for the cabinet design was making sure that it was as compact as possible. To achieve this goal, NPI needed to streamline the organization of all internal components and supplemental wiring.

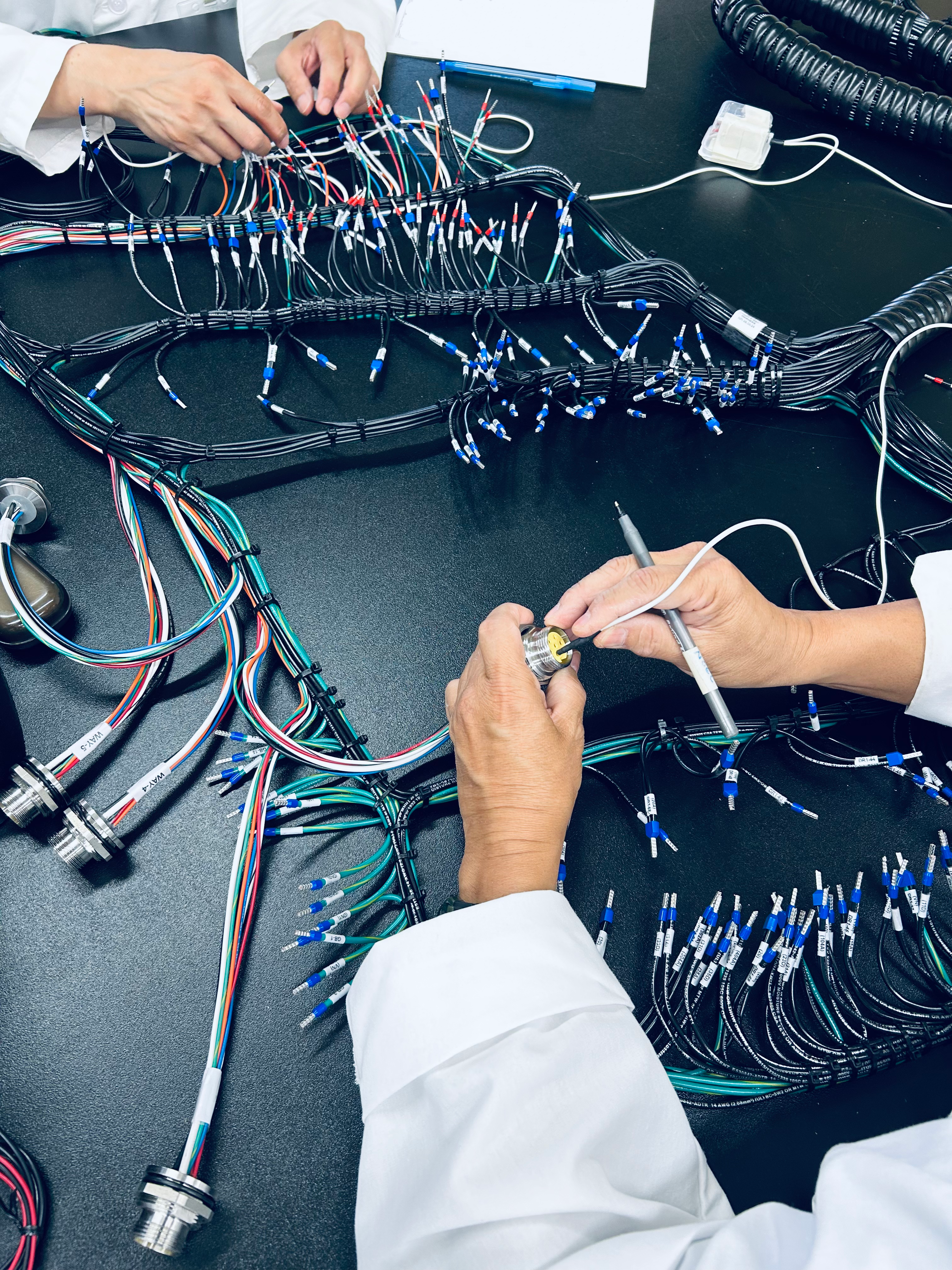

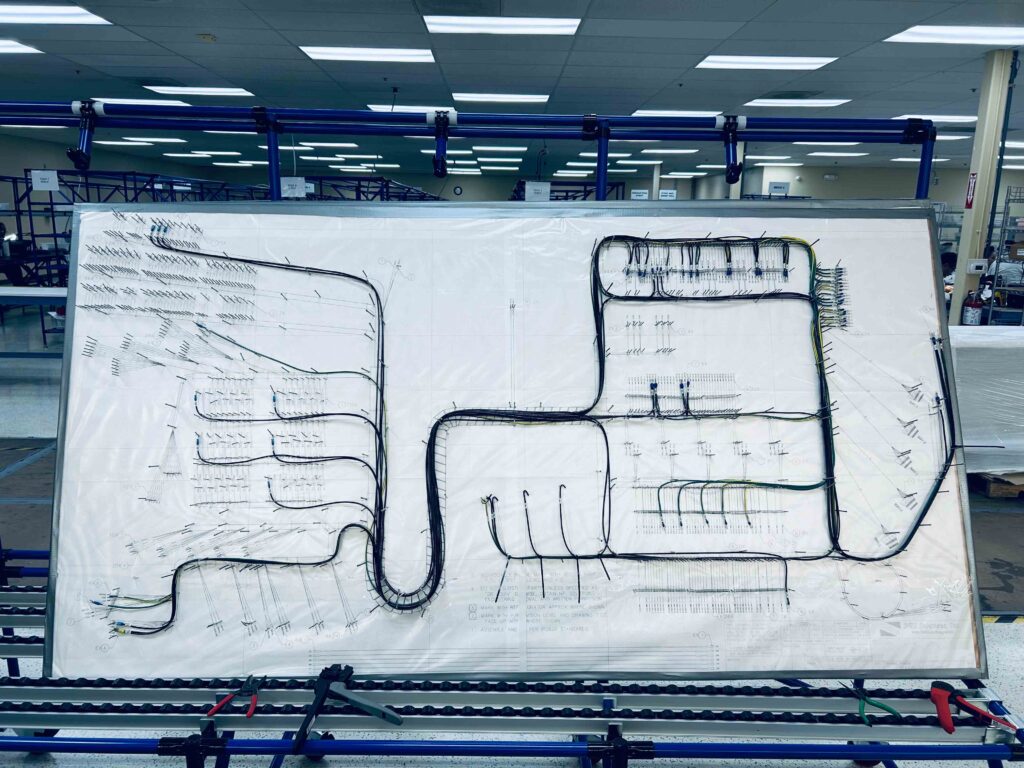

3. Cable Harness

Power and signal cables were strategically routed to minimize cross-talk and provide proper service loops and mounting points in the cabinet. Proper routing of power and signal cables also helped minimize the overall cabinet size.

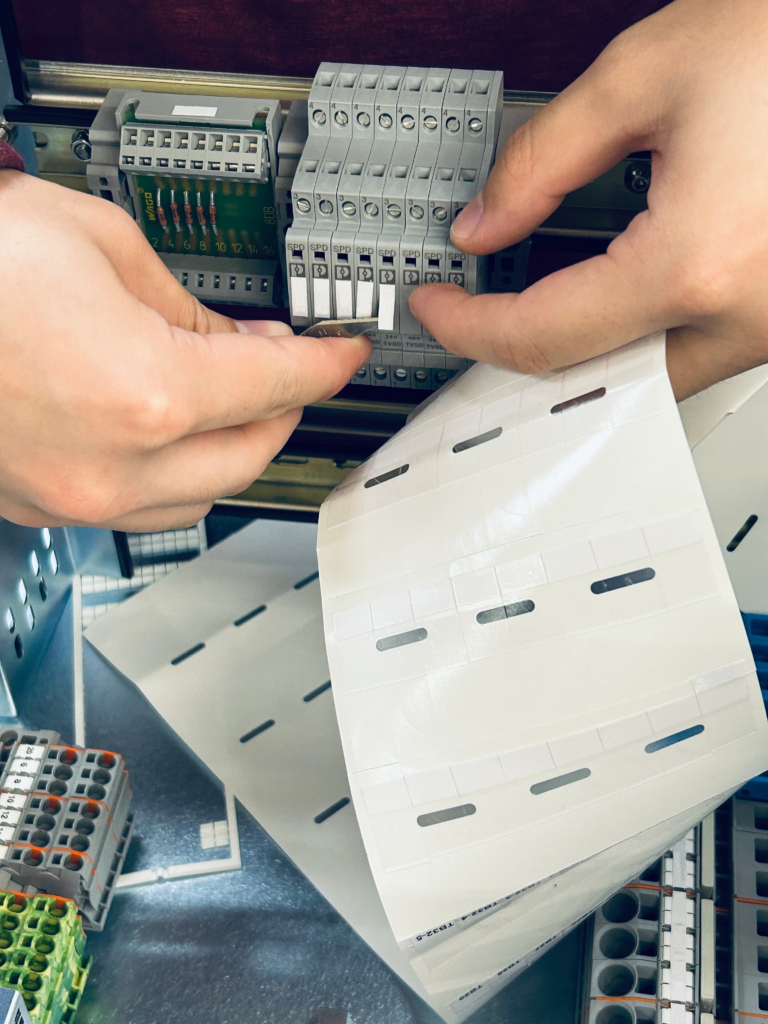

4. Cable connections

Minimizing the connector count by having multiple signals in one large connector. Reducing connection points within the cabinet reduced the possibility of independent systems failing and made troubleshooting potential challenges in the field easier for the scientists and technicians monitoring off-shore fish farms.

5. Bulkhead mounting of connectors

NPI Solutions considered the presence of water, freezing temperatures, and rough seas when determining the proper connections for the end environment. This improved reliability during use and minimized the possibility of data gaps or the final product returning unreliable information.

6. Shipping

NPI Solutions worked closely with packaging engineers to create a shipping container that protected the sensitive equipment and also implemented removable handles located on the cabinet that were ergonomically positioned to lift and position the cabinet. Considering these units were traveling great distances by both plane and boat with delicate data measuring equipment and vision systems, ensuring they arrived in pristine condition was paramount to their final performance.

The Results

After months of design and development using our experience in electronic assembly manufacturing, NPI Solutions was able to deliver a comprehensive system that could withstand frigid temperatures, corrosive environments, and strong ocean currents in remote northern locations. The scientists at the marine research center were now able to continuously collect data that would help to develop future trends without the need for actual human intervention at the data collection sites.

The data measuring electronics and vision systems within these cabinets quickly advanced scientific studies without requiring human intervention that could alter the viability of the final research.

NPI Solutions is proud to use our expertise in electronic assembly manufacturing to help researchers better understand and protect the ocean ecosystems that are vital to the future of humanity. If you have a project like this or any other needs for electronic assembly manufacturing, you can reach a member of our team through the contact link below. With locations in California, Mexico, China, and Singapore, the NPI Solutions team is always looking for a new challenge when it comes to contract design, custom manufacturing, and any technical service for complex electro-mechanical assemblies.